OUR BRANDS

OUR BEST TEXTILE MACHINERIES

WNS Gas (or oil) Fired Boiler

Stepless pressure regulation S-Roll calender(Single pressure type)

SHEARING MACHINES

RAISING MACHINE DOUBLE DRUM [2G28 ]

M5469 stentering boarding machine

Film calender (double side pressure three roller calender)

Easy-Supreme Touch 6.2 Sueding Machine

EASY SUPREME TOUCH 8.1(SMART SYSTEM) SUEDING MACHINE

DUST CLEANING BRUSHING MACHINE SP200X2 for knits fabrics

CARU

AS4 Wet & Dry sueding

BATCHING

BRUSH, DIAMOND, EMERY, TRIMMING MACHINE

CENTERING DEVICE

CORDUROY ACCESSORIES, GUIDES, KNIVES AND SPACERS

CORDUROY BLADE SHARPENING

CORDUROY CUTTING

CORDUROY DRY BRUSHING

CORDUROY WET BRUSHING

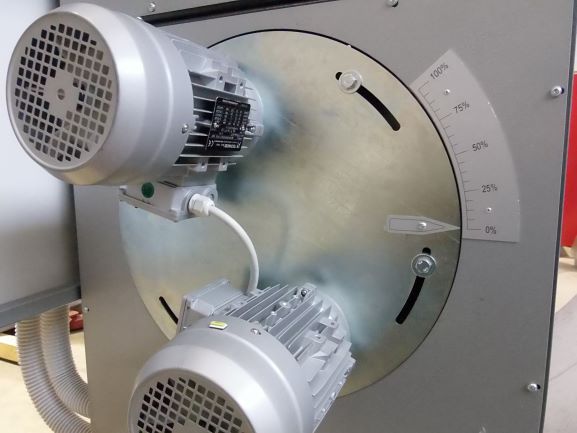

DUST CLEANING BRUSHING MACHINE SP200

DUST CLEANING BRUSHING MACHINE SP200 x2 for woven fabrics

DUST CLEANING BRUSHING MACHINE SP200X2 for knits fabrics

DUST CLEANING BRUSHING MACHINES

EASY SUPREME TOUCH 8.1(SMART SYSTEM) SUEDING MACHINE

Easy-Supreme Touch 6.2 Sueding Machine

SHAOYANG

5473 stenter setting machine

M5469 stentering boarding machine

M5471 knitting stentering boarding machine

Mazza Gianni S.a.s

CUTTER CYLINDER

Description

The aim of this cylinder is the cutting and the elimination of the yarns that aren’t levelled by the shearing machineManufacturing Features

- Manufactured in tube in a special steel, rectified and chromium-plated

- Pivots rectified and shrinking on

- Blades support in stainless steel

- Cutter applied following the working need

- Manufactured by respecting the dimensions and the features chosen by the Customer

- The materials and the working processes used, grant the respect of the functional features and of the safety regulations

Functional Features

- Dynamic balancing with certification related to the speed required by the Customer

- Longitudinal and torsional rigidity suitable for avoiding undesired deformations vibration

- Maximum simplicity in the substitution of the damaged cutters

- Long working life even in hard exercise conditions

CYLINDER BRUSH

Description

The aim of these brushes is the cleaning, the polishing of the fabric during the different working phases, especially in the working and in the finishing of the fabrics in woolManufacturing Features

- Internal part in tube in stell

- Pivots in steel, shrinking on

- Covered with tube in moplen

- Trimmed with horse hair, bristle, nylon, tampico

- The bristle disposition can be full, helical, bi-helical

- Turned and levelled external surface for a perfect circularity and concentricity respect to the axe of rotation

- Manufactured by respecting the dimensions and the features chosen by the Customer

- The materials and the working processes used, grant the respect of the functional features and of the safety regulations

Functional Features

- Dynamic balacing with certification related to the speed required by the Customer

- Longitudinal and torsional rigidity suitable for avoiding undesired deformations and vibrations

- Long working life even in hard exercise conditions

CYLINDER BRUSH FOR PRINTING MACHINE

Description

These cylinder brush are able to remove the traces of colour left on carpets during the printing phaseManufacturing Features

- Internal part tube in steel

- Heads and pivots in steel or inox, shrinking on. The pivots are rectified and if required, they are fixed by screws in order to facilitate the substitution

- There is a special covering for the tube in steel in order to avoid the corrosion due the chemical agents

- The bristle disposition can be full, helical and bi-helical

- Normally trimmed with bristles in nylon, but on request, it can be supplied with any other kind of material

- Turned and levelled surface for a perfect circularity and concentricity respect to the axe of rotation

- Manufactured by respecting the dimensions and the features chosen by the Customer

- The materials and the working processes used, grant the respect of the functional features and of the safety regulations

CYLINDER BRUSH FOR REASING MACHINE IN EXTRUSION IN ALVEOLAR ALUMINIUM

Description

The aim of this cylinder is the cleaning of the reasing cylinder. With this new brush typology it has been possible to insert the simple interchangeability of the damaged brush plates, by reducing in a satisfactory way the stop of the machine and, in the meanwhile, it has been inserted a new support concept in alveolar aluminium that reduces notably the mass in rotation.Manufacturing Features

- Internal part in alveolar aluminium patented

- Pivots in steel, rectified, and shrinking on

- Covered with staves in aluminium patented for the brush plates fixing in nylon or metallic

- Turned and levelled external surface for a perfect circularity and concentricity respect to the axe of rotation

- Manufactured by respecting the dimensions and the features chosen by the Customer

- The materials and the working processes used, grant the respect of the function al features and of the safety regulations

Functional Features

- Dynamic balancing with certification related to the speed required by the Customer

CYLINDER BRUSH FOR WOOL CARDING

Description

The aim of the carding is to realize the fibres separation, by releasing them from the impurities still present and by completing the opening and the cleaning started in the previous passages. The cylinder has to keep clean the carding rolls during the working processManufacturing Features

- Internal part in tube in steel

- Heads and pivots in steel shrinking on

- The pivots are rectified

- Covered with staves in wood

- Covered with jacket in aluminium

- Normally trimmed with bristles in tampico or in a special mixing, in order to eliminate the electrostatic electricity accumulation

- Turned and levelled external surface for a perfect circularity and concentricity respect to the axe of rotation

- Manufactured by respecting the dimensions and the features chosen by the Customer

- The materials and the working processes used, grant the respect of the functional features and of the safety regulations

Functional Features

- Dynamic balacing with certification, related to the speed required by the Costumer

CYLINDER BRUSH WITH THERE STAVES FOR THE RAISING MACHINE

Description

The aim of this cylinder is the cleaning of the teasiling cylinder. With this new brush typology, it has been possible to insert the simple interchangeability, of the damaged brush plates, by reducing in a satisfactory, way the stop of the machine and it has been possible to insert brushes with elevated heights until 4600mm. Thanks to the special antivibrating element that makes them more rigid and more compactManufacturing Features

- Internal part in tube in special steel

- Special antivibrating element

- Pivots in steel, rectified and shrinking on

- Covered with staves in aluminium patented for the brush plates fixing in nylon or metallic

- Turned and levelled external surface for a perfect circularity and concentricity respect to the axe of rotation

- Manufactured by respecting the dimensions and the features chosen by the Customer

- The materials and the working processes used, gran the respect of the functional features and of the safety regulations

Functional Features

- Dynamic balancing with certification related to the speed required by the Customer

- Longitudinal and torsional rigidity suitable for avoiding undesired deformations and vibrations

- Maximum simplicity in the substitute on the damaged brush plates

- Long working life even in hard exercise conditions

LAPPING BRUSHES

Description

The aim of these bushes is to have a homogeneous lapping effect, avoiding any problems of rows and folds over the entire surface of the fabric.Manufacturing Features

- Manufactured with a tube of special steel

- The pins are ground and hot introduced

- A wide choice of grain and abrasive section

- The hole is specially arranged so to allow the tissue to remain stretched all the time

- Manufactured in accordance with the Costumer’s dimensions and features

- The materials and the machining processes we use are a guarantee for complying with the functional features and the safety standards

Functional Features

- Dynamic balance with certification, based on the speed requested by the Customer

- Longitudinal and torsion stiffness suitable for avoiding unwanted deformation and vibrations

- A high resistance of the abrasive bristles, even under hard working conditions and on several kinds of tissues

LAPPING BRUSHES EQUIPPED WITH CERAMIC COATED BRISTLES

Description

The iam of these brushes is to have a homogenous effect of grinding, avoiding problems of rows and folds over the entire surface, producing new effects on the fabricManufacturing Features

- Manufactured in a special aluminium

- Bristles in rilsan resistant at high temperatures

- The bristles are placed on a tile in aluminium with hand-made sewings, in order to grant a higher bristle tightness, for the great effort to which it is subjected

- Turned and levelled external surface for a perfect circillarity and concentricity respect to the axe of rotation

- Manufactured by respecting the dimensions and the features chosen by the Customer

- The materials and the working processes used, grant the respect of the function al features and of the safety regulations

Functional Features

- Possibility to assemble the tiles on the surface of any other cylinder

- Maximum easyness in the substitution of the damaged tiles

- Long working life even in hard exercise conditions

RIBBONS BRUSH TRIMMED

Description

The aim of these ribbons is the interchange ability simplicity, at the present in use both for the teasiling machine and for the wool carding machines and for the other workings where there is the need of an immediately replacementManufacturing Features

- Manufatured with a special base, with more levels, that allows to avoid deformations during the working phases

- The trimming can be with the application of horse hair, bristle, nylon, tampico

- The materials and the working processes used, grant the respect of the functional features and of the safety regulations

Functional Features

- Application simplicity on any surface, circular of flat

- Longitudinal and torsional rigidity suitable for avoiding undesired deformations

- Long working life even in hard exercise conditions

Jiangsu Xinlian

Clip / Roller Mercerizing Range

CPB ( Cold Pad Batch) Machine

Sanforizing machine

Washing Range after printing/Dyeing

Broadenwin

BENDCON-Y

Film calender (double side pressure three roller calender)

Stepless pressure regulation S-Roll calender(Double side pressure type)

Stepless pressure regulation S-Roll calender(Single pressure type)

Two-roll calender

YUANDA BOILER

WNS Gas (or oil) Fired Boiler

LSS Once Through Steam Boiler

Diesel / Heavy Oil Boiler

Rice Husk Fired(rice mill) Boiler

Electric Steam Boiler

Vacuum Hot Water Boiler

SPARE PARTS

Azbil Temperature controller-C26TR0UA2000

Burner Controller LQA-24

Product Specification

| Voltage | 220-240 V |

| Frequency | 50/60 Hz |

| Input Voltage | 3 VA |

| TS Max | 10s |

| Minimum Order Quantity | 1 |

Erhardt+Leimer Digital Controller DC5501

Erhardt+Leimer Digital Controller DC5501

Gefran Load Cell

- Brand:GEFRAN

- Condition:New Other

- SKU:SD20787

- Model:TR-N2C-C40-1

- MPN:TR-N2C-C40-1

- Country of Manufacture:ITALY

- Manufacturer:GEFRAN

INFRARED CENTERING EQUIPMENT

INFRARED EDGE ALIGNMENT SERIES

Infrared edge sensor FR 5503

Product description

- Used for optical and mechanical scanning of web edges in tenters

- Infrared edge sensor based on the reflection principle

- Reliable scanning of the web edge even on contrast-rich printed materials and low-reflective colors

- In case of uneven web edges, mechanical scanning by pivoting in the scanning lever will dampen the control

- Measuring range: ±10 mm

Technical Specifications

| Nominal supply voltage | 24 V DC |

| Permitted supply voltage range | 20 to 30 V DC (ripple included) |

| Current consumption | 100 mA |

| Power consumption | 2.4 W |

| Scanning frequency | 100 Hz |

| Measuring range | +/- 10 mm |

| Distance edge sensor - web | 36 mm |

| Protection class | Max. IP 65 with suitable connector inserted |

| Ambient temperature | +10 °C to +60 °C |

| Storage temperature | -10 °C to +80 °C |

| Weight without scanning lever | 0.37 kg |

| Weight with scanning lever | 0.46 kg |

LME 21.130 C2

| Manufacturer item no.: | LME 21.130 C2 |

| Type: | LME 21.130 C2 |

| Brand: | Siemens |

AUTOMATION PRODUCTS

Rotary Encoder

HSV-180AD AC380V Servo Drive

- High Performance AC digital servo drive

- Easy and flexible control (five control modes)

- Full state display

- Various interface and control modes

- Applicable to situations that requires high speed and high power

- Double encoder interfaces that can be connected to position feedback components such as grating ruler to form full-closed loop position control system

Proximity Sensor

- Suitable for multiple applications with high performance

- Metal case for easy installation and protection

- Brilliant indicator light for easy viewing of work status

- Internal glue, fixed circuit board, good shock resistance

- Optimized circuit design, good EMC performance

- The wrong polarity of the power supply will not damage the product

HV480 Series High Performance Frequency Inverter

HV390 Series Mini Design Frequency Inverter

1. Advanced motor control technology support both Open loop vector control(SVC) and V/F control.

2. Different input voltage( 220V single phase/220V 3 phase/380V 3 phase/460V 3 phase).

3. High starting torque characteristics and precise speed control.

4. Suitable for all regions which have different grid and voltage.

5. All product type integrate force-cooling fan.

6. Built in simple PLC, PID , programmable I/O terminals, RS485 interface, analog input / output control function and other rich control functions

7. Mini design housing suitable for micro automation such as packaging machine, labeling machine, conveyor belt etc

H-BOX

HV590 Series FVC High Performance Frequency Inverter

HT3000 IoT HMI

HCS Series Card type PLC

Photoelectric Sensor

HHS Series High Performance Soft Starter

HHS series of soft starter is the latest development of HNC has an international leading technology of intelligent AC motor soft starter. HHS Series Soft Starter uses the power electronic technology, the microprocessor technology and the modern control theory technology, has the present international advanced level the new starting equipment. This product can effectively limit the starting current of asynchronous motor, which can be widely used in fan, water pump, compressor and other transportation and heavy equipment, is the star delta conversion, autotransformer, magnetron step-down start ideal replacement equipment.

HHS series of soft starter has excellent performance with the international high-end soft starter of the same, further strengthen the product reliability and environmental adaptability, humanization and professional design, can meet various application requirements.

......................................................................FEATURES........................................................................

1. Multi start mode: The maximum output torque can be obtained by the voltage ramp mode. The maximum current can be obtained by the constant current soft starter mode, which can be applied to the load with large static friction force 2. High reliability: The high performance microprocessor is used to process the signal in the control system, so as to avoid the excessive adjustment of the analog circuit in the past, so as to obtain excellent accuracy and execution speed 3. High performance: Programmable delay start mode, programmable interlocks control No sequence requirements for input power Starting time, parking time can be modified Dynamic fault memory function, easy to find the cause of the fault, up to ten faults can be recorded 4. Field bus full dynamic control monitoring starter, easy networking: Bus type is MODBUS. 5. Variety of protection functions: Protection against over voltage, under voltage, over temperature, phase loss, motor overload, etc.。 6. English character display function: LCD display a variety of operating parameters, programming and fault state with text prompts 7. Perfect humanized design: Beautiful appearance and reasonable structure Perfect function and simple operation Solid, reliable and compact The artistic design of industrial products 8. Reliable quality assurance: Computer simulation design STM patch production process Excellent electromagnetic compatibility High temperature aging, vibration test before the factory 9. Quick and thoughtful after-sales service: Reliable performance and quality lay the foundation for quality service Provide excellent and complete equipment design Timely and thoughtful use of consulting Continuously improve product performance according to user opinion.HV580L Series Elevator Inverter

-

1. Smooth ride performance

-

2. Integrated brake control

-

3. Default factory setting user friendly factory, get you started quickly.

-

4. 4-Indepenent S-Ramps

-

5. Programmable DC –injection braking

-

6. Complete functions for elevator application

ZHAOJIN

INFRARED CENTERING EQUIPMENT

INFRARED EDGE ALIGNMENT SERIES

PACKAGING MACHINERY

REPAIRING SERVICE

YILDIZ MAKİNA SAN-TURKIYE

Knit Dyeing machine, slitting machine, Squeezer machine, Stenter Entry process Pre-Heating, Relax Dryer Entry Process Pre-Heating, Wet Fabric Reversing Machine, Fabric Preparation Machine. Cold Bleaching Machine, EDGE Sewing Machine.