CORDUROY WET BRUSHING

CORDUROY WET BRUSHING

Description:

Corduroy wet brushing machine.

This machine can brush all kind of corduroy, special cross brushes belts are installed at the bottom and rotary brushes are in the top of the machine; Spring water system let's to wet the fabrics constantly during the process. The water is recycled by an automatic filter unit.

WET BRUSHING.

To develop a good quality corduroy,

the wet brushing is the most important step in all corduroy finishing process.

Due to the water that swells the natural fibers, the brush action is much more effective;

Wet brush process let's easily form good quality shape of corduroy's whales.

BNR2 X 2 - HIGH SPEED CORDUROY WET BRUSHING MACHINES

BNR2 WET BRUSHING WITH SQUEEZER

Characteristics:

CORDUROY BRUSHING MACHINE

This system is the risult of more than forty years of experience in the

specific field of corduroy.

The brushing machines ANR2 and BNR2 have been specifically planned

and realized for the continuous brushing of corduroy fabrics.

PATENTS protects the innovation introduced which have made those

brushing machine the most technologically advanced machine and

above all the only in conformity with CE standards.

CPB ( Cold Pad Batch) Machine

CPB ( Cold Pad Batch) Machine

Diesel / Heavy Oil Boiler

Diesel / Heavy Oil Boiler

Yuanda Boiler since 1956

Oil fired boiler is the 3-pass wet back boiler, can produce steam or hot water. This type boilers are fully automatic, safe, energy saving and designed to operate on a wide range of liquid and gaseous fuels like heavy oil, light oil, gas, and dual fuel options.

Output: steam

Capacity: 0.5-40 ton/h, 15hp-2500hp

Styles: horizontal

Available Fuel: heavy oil, diesel, furnace oil, waste oil, dual fuel, etc

Applied Industries: food, beverage, diaries, feed mill, garment, textile mill, paper mill, packaged, refinery, chemical, laundry, hotel, greenhouse etc

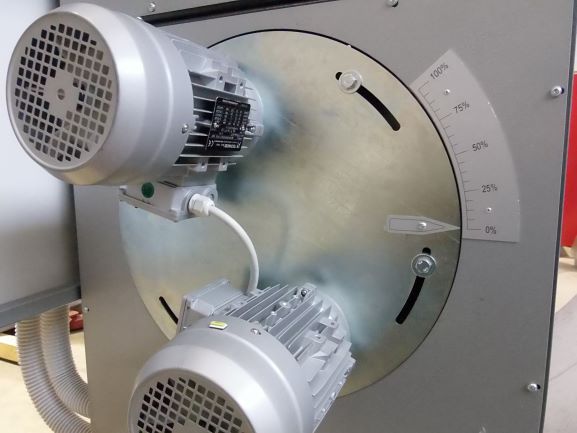

DUST CLEANING BRUSHING MACHINE SP200 x2 for woven fabrics

DUST CLEANING BRUSHING MACHINE SP200 x2 for woven fabrics

Description:

LINT/ DUST REMOVAL MACHINE

SP200 x 2 for woven fabrics

This brushing/cleaning machines is a COMBINATION of three actions:

beating / brushing / sucking.

Beating is made by beaters rollers and brush by the means of brush rollers,

sucking is made from an efficient air sucking system that catch the removed dust / lint and collect them to an external filter unit.

Brushes and beaters rollers are working at the same time on front and on back sideof the fabric to assure the maximum cleaning efficiency.

The entire units is made of mild-steel.

Some parts for their particular constitution and function, are galvanized coating and the frames are treated with epoxy paints.

This brushing/cleaning machines is an efficient group easily applicable

to any other machine or in a line of processing machines.

Its dimension let it to be suitable for different applications.

Additional air blades can be installed in the machine; The air blades are blowing ionised high air pressure that let's the stubborn static dust to be roved easily from fabric surface.

Characteristics:

Machine suitable for heavy woven fabrics as denim, home textile fabrics.

Individual motor for each brush;

4 sets of nylon hair brushes made of helical bristles shape;

High pressure motor fan for air-blades;

2 set of high pressure air-blades;

4 ionized bars positioned inside the air-blades;

Windows for easy access inside the machine;

Load cell or dancing roller for tension control of fabrics;

Electric panel with inverters control for fabric pulling and speed of brushes;

Batching roller at outlet;

Complete suction unit, with motor-fan and filter bags ;

DUST CLEANING BRUSHING MACHINE SP200X2 for knits fabrics

DUST CLEANING BRUSHING MACHINE SP200X2 for knits fabrics

Description:

DUST CLEANING MACHINE

BRUSHING MACHINE TYPE SP200X2 FOR KNITS FABRICS

This brushing/cleaning machines is a COMBINATION of three actions:

beating / brushing / sucking.

Beating is made by beaters rollers and brush by the means of brush rollers,

sucking is made from an efficient air sucking system that catch the removed dust / lint and collect them to an external filter unit.

Brushes and beaters rollers are working at the same time on front and on back sideof the fabric to assure the maximum cleaning efficiency.

The entire units is made of mild-steel.

Some parts for their particular constitution and function, are galvanized coating and the frames are treated with epoxy paints.

Additional air blades can be installed in the machine; The air blades are blowing ionised high air pressure that let's the stubborn static dust to be roved easily from fabric surface.

Characteristics:

Dust Cleaning Brushing machines, Type SP200X2 with;

Inlet with adjustable tensioning bar;

Double adjustable expander unit with Two motorized scroll rollers adjustable at 360°;

Centering device type “Slatted drum” with feeding motor and photocells for centering;

Individual motor for each brush;

2 sets of beaters rollers made by stainless steel star-shape;

2 sets of Horse hair brushes made by straight bars bristles shape;

Electric actuators for brush distance position. ( EXCLUSIVE FROM CARU’)

Transparent windows for easy access in to the machine;

Electric panel with inverter for fabrics drive;

Distance sensor for no-tension control of the running fabrics with accumulation cradle ( EXCLUSIVE INNOVATION FROM CARU’);

Outlet motor roller with plaiter unit at outlet ;

Complete suction, with motor-fan and filter bags unit;

DUST CLEANING BRUSHING MACHINES

DUST CLEANING BRUSHING MACHINES

Description:

LINT/ DUST REMOVAL MACHINE

High power brushing machines suitable for all fabric cleaning operations, where traditional brushes can not obtain positive effects.

Clean using ionizing air flow technology.

Neutralizes Surface Charges

The machine is equipped with 4 high pressure air-blades, each one with individual motor-fan;

Each air-blade has one ionized bar to ionize the air flow blowing on fabrics.

This system remove the static from fabrics making easy to remove surface particles dust.

Individual motor for each brush;

4 sets of nylon hair brushes made of helical bristles shape;

2 High pressure motor fan for air-blades;

4 set of high pressure air-blades;

4 ionized bars positioned inside the air-blades;

Windows for easy access inside the machine;

Load cell or dancing roller for tension control of fabrics;

Electric panel with inverters control for fabric pulling and speed of brushes;

Batching roller at outlet;

Complete suction unit, with motor-fan and filter bags ;

EASY SUPREME TOUCH 8.1(SMART SYSTEM) SUEDING MACHINE

NEW EASY SUPREME TOUCH 8.1 SMART SYSTEM [Enhancement, knowledge and innovation.]

Description:

MACHINE WITH INNOVATIVE TENSION CONTROL SYSTEM

NEW SUEDING MACHINE EASY SUPREME TOUCH 8.1 SMART

THE ULTIMATE NOVELTIES

The long experience gained in sueding, along with the close co-operation with customers, enabled Caru' to set up a specific machines making technique,

having the first-rate production as final target to achieve the highest quality in fabric finishing.

The new machine "EST 8.1" is a SUEDING MACHINE having 8 sueding rollers full covered of diamong emery,

8 (height) Sueding rollers with a Diam. of 200mm dynamically balanced with clamping/tensioning device for abrasive tape. Abrasive brushes can also be use.

Process fabrics with 8 sueding rollers on one side of the fabrics or 4 sueding rollers on right side and 4 sueding rollers on back side of the fabric.

Sueding rollers NO. 1 – 3 – 6 – 8, are provide with oscillating motion system.

Jointless Diamond tapes;One entire belt, high resistancy, it can be

reinstalled on the roller many times and every time without be damaged.

In all Caru's machines,the sueding rollers can be made in light weight composite carbon fibre, which are more light and strong, giving advantage of high rotary speed and assure a perfect stability.

Characteristics:

Diamond and Abrasive brushes can be used in this machine.

Easy-Supreme Touch 6.2 Sueding Machine

Easy-Supreme Touch 6.2

Description:

SUEDING MACHINE EASY- SUPREME TOUCH 6.2 FOR SUEDING/BRUSHING & DIAMOND FINISHING

Caru’ introduced in the market the last version of the new EASY SUPREME TOUCH 6.2 with innovative features; The EASY SUPREME TOUCH 6.2 is a machine using abrasive brushes and diamond emery in combination; 6 units of brushes or sueding rollers are the standard setting, extendable to 8 units on requirement. Sueding is a very complex process influenced by several parameters and the results are not only gauged by the touch assessment but also from the visual assessment, an high level of reproducibility and flexibility are also required nowadays.

THE COMPLETE MACHINE FOR YOUR PRODUCTION.

Characteristics:

THE ULTIMATE NOVELTIES

The long experience gained in sueding, along with the close co-operation with customers, enabled Caru' to set up a specific machines making technique,

having the first-rate production as final target to achieve the highest quality in fabric finishing.

The NEW sueding & brushing machine EASY- SUPREME TOUCH 6.2" can use abrasive brushes or sueding rollers

covered with emery, paper or diamond. The machine can be use in combination giving special range of different effects

Brushes or sueding rollers which rotate at a variable speed lets to obtain excellent sueding results

both on knitted and on woven fabrics.

This machine is characterised by its high sueding efficiency due to a considerable number of contact-points and adjustments.

Right and reverse side of the fabric can be processed on one passage.

Diamond tape are made without joint, on one entire belt very strong and resistent that can be

reinstalled on the roller many times and every time without be damaged.

As on all Caru's machines, the sueding rollers can be made in light weight composite carbon fibre, which are more light and

strong, giving advantage of high rotary speed and assure a perfect stability.

Electric Steam Boiler

Electric Steam Boiler

Electric steam generator boiler | Horizontal electric boiler | Eco-friendly boiler

Horizontal electric automatic boiler is a kind of 99.8% efficiency which takes electricity as energy. It has the advantages of environmental protection, no pollution, no noise, convenient installation, small occupation

Output: steam

Thermal Capacity: 0.2ton/h-4ton/h 100kg/h-4000kg/h

Styles: horizontal or vertical

Powered by: electricity

Applied Industries: food, beverage, diaries, feed mill, garment, textile mill, paper mill, packaged, refinery, chemical, laundry, hotel, greenhouse etc

Film calender (double side pressure three roller calender)

Film calender (double side pressure three roller calender)

This machine can be applied to pure cotton, chemical fiber, hemp, wool spinning and blended fabric calendering finishing;the middle roller of the equipment is fixed roller, the upper and lower rollers can respectively to the intermediate pressure. When the fabric pass the machine once, it can be calendering one time or be twice. After calendering the fabrics can achieve evenly shiny and good touching feeling. The equipment is also very save costs.

Product advantages:1.Nominal width: 1800-5000mm

2.Working speed: 20-70m / min

3.Design pressure: 60-120T